86-571-26265158

During the reflow process of the printed circuit board (PCB), the setting of the reflow temperature curve will greatly affect the strength of the solder joints. It is not only necessary to ensure that each solder joint meets the quality requirements, but also to ensure that the components and boards are not damaged.

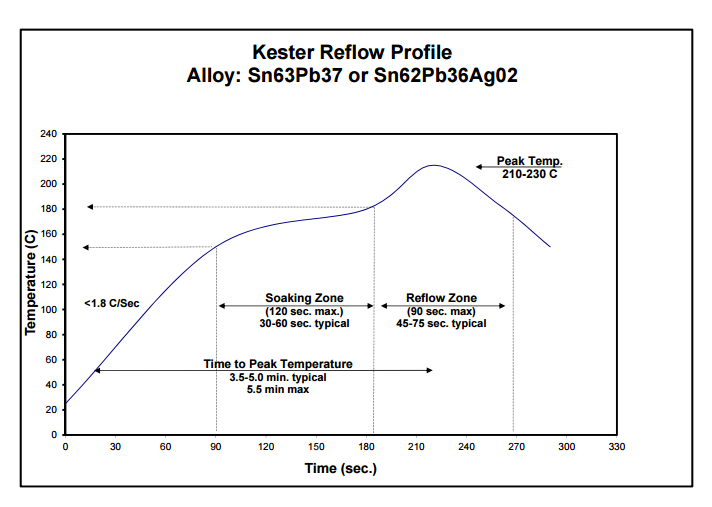

The temperature curve is a function of the temperature applied to the component versus time, and it is specifically expressed as a curve of the temperature of the component on the circuit board with time during the reflow process. Theoretically ideal temperature curve consists of preheating zone, heat preservation zone (active zone), heating zone (reflow zone) and cooling zone. The first three zones are heated, and the last zone is cooled.

① In the preheating zone, heat the board from room temperature to around 150°. Preheating is to activate the solder paste and to avoid the rapid high temperature heating during the immersion of tin, which will cause defective parts. The goal of this area is to heat the board at room temperature as soon as possible, and the heating rate should be controlled within an appropriate range. If the temperature rises too fast, thermal shock will occur, and the boards and components may be damaged; if the temperature rises too slowly, the solvent will not evaporate adequately and affect the soldering quality.

②Insulation area (active area), generally 150°~180°, within 200°. The activity of the solder paste is the strongest in this temperature range, and it is maintained for about 90s. The main purpose of the insulation stage is to stabilize the temperature of the internal components of the reflow oven, and to minimize the temperature difference of each part. Stay in this area for enough time to make the temperature of the larger components catch up with the temperature of the smaller components, and ensure that the flux in the solder paste is fully volatilized. At the end of the insulation stage, the oxides on the bonding pad, solder balls and component pins are removed under the action of the flux, and the temperature of the entire circuit board is also balanced.

③In the heating zone (reflow zone), the solder paste begins to melt and the time is between 60s and 90s. In this area, the heater temperature is set to the highest, so that the internal temperature quickly rises to the peak temperature. The peak temperature of the reflow curve is usually determined by the melting point temperature of the solder paste and the heat-resistant temperature of the boards and components. The peak temperature also varies depending on the solder paste used. Generally, the maximum temperature of lead-free solder paste is 230°-250°, and the maximum temperature of lead-containing solder paste is 210°-230°. Pay attention to the time in the heating zone not to be too long to prevent damage to the inner wall of the reflow oven, damage to electronic components or scorching of the circuit boards.

④ In the cooling zone, quickly reduce the temperature to solidify the solder paste. In this area, the temperature is cooled to below the solid phase temperature to solidify the solder joints. The cooling rate will have an impact on the strength of the solder joints. If the cooling rate is too slow, it will cause excessive eutectic metal compounds to be produced, and a large grain structure will appear at the solder joints, making the strength of the solder joint lower.

The reflow temperature curve of Sn63Pb37 solder paste is shown in the figure:

In actual production, the solder paste supplier will provide the reflow temperature curve. And the users can set the temperature curve with the assistance of the engineer.