86-571-26265158

To ensure the consistent quality of our products, Tronstol conducts strict quality control throughout the whole production process.

Department: Quality Control Department

Content: When the materials reach the inspection area, the quantity is counted according to the delivery note. Then the inspection is carried out according to the relevant inspection standards: such as checking the drawings. Qualified products are placed in the qualified area. And the unqualified products are rejected and returned to the purchasing department with an explanation.

Purpose: Guarantee the qualified rate of production materials and reduce the secondary processing of production.

Department: Warehousing Department

Content: According to the production plan of the production department, the warehouse management personnel receive the corresponding materials according to the bill of materials to the production department.

Purpose: Ensure that the production department completes production in time, without missing any materials.

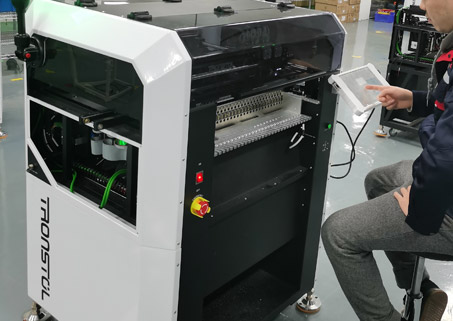

Department: Production Department

Content: Assemble in an orderly manner according to the production assembly instructions.

Purpose: Ensure that the sales team can meet the customer's delivery date and product quality.

Department: Warehousing Department

Content: Warehouse management personnel ensure that the quantity in the warehouse is consistent with the actual materials, and make data statistics.

Purpose: Ensure that the fixed assets of the warehouse are not missing or omitted.

Department: In Process Quality Control

Content: Process monitoring of each equipment according to the SOP of process inspection.

Purpose: Ensure that the equipment has no quality defects and no apparent defects.

Department: Final Quality Control

Content: Strict inspection according to the relevant inspection SOP of the product such as product function, machinery, appearance, voltage, etc.

Purpose: Guarantee equipment yield.

Department: Final Quality Control

Content: According to the sales order, carry out all-round inspection of the product, including voltage, appearance, function, transportation inspection, etc.

Purpose: Ensure that customers can receive satisfactory machines.

Department: Logistics Department

Content: According to the sales invoice, check the accessories, check the SN.No, and strictly implement the SOP of the packaging process.

Purpose: Ensure that the equipment will not have any packaging defects during transportation, and allow customers to receive the machine in good condition.