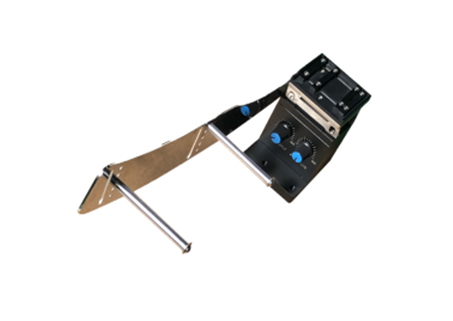

Solder Paste Mixer Specification

| Model | Solder paste mixer |

| Speed | Motor speed:1350RPM |

| One revolution:400RPM;Second rotation:300RPM |

| Capacity | 0-1000 g*2 cans |

| Can accept solder paste cans | DiameterΦ60-Φ67 Standard(Suitable for general 500g solder paste cans) |

| Time setting | 0.01s~99H99s, Minute and the second setting |

| Display method | LED |

| Peak Power(KW) | 60W |

| Input Voltage(V) | AC 220V±10% 50Hz |

| Dimension | L400*W400*H500mm |

| Packing size | 520*520*580mm |

| Net weight | 45kg |

| Gross weight | 50KG |

Solder Paste Mixer Features

The solder paste mixer uses the revolution to generate centrifugal force, and the force generated by the rotation at an angle of 45 degrees with the revolution axis makes the solder paste at the upper end of the tank continuously move downwards, while the solder paste at the bottom of the tank moves from the periphery to the top of the tank. Forming a whirlwind funnel-shaped stirring action, which can smoothly stir and soften the solder paste, defoam and reach an appropriate viscosity. After stirring, the solder paste has good wettability, uniform diffusion, excellent printing effect, and achieves the best flux performance during welding. Its characteristics are as follows:

Special control circuit, adjustable mixing time, convenient operation.

The solder paste is placed at 45 degrees and rotates along the axis of the axis so that the solder paste will not adhere to the can lid.

Stable operation, low noise, with the effect of natural temperature recovery and clear air bubbles during the mixing process.

The solder paste tank does not need to open the lid, it is convenient and safe to take and place.

With safety devices to ensure personal safety.

SMT Solder Paste Types

Solder paste is a new type of soldering material. It is a paste-like mixture formed by mixing solder powder, flux and other surfactants, thixotropic agents, etc. It is mainly used for the welding of electronic components such as PCB surface resistance, capacitors and IC in the SMT industry.

According to the flux is divided into three categories

1. Ordinary rosin cleaning type is divided into RA and RMA: This type of solder paste shows a better "tinning speed" during the welding process and can ensure a good "welding effect"; after the welding work is completed, the rosin residue on the PCB surface is relatively high. It can be cleaned with appropriate cleaning agent. After cleaning, the board surface is smooth and free of residues, which ensures that the cleaned board surface has good insulation resistance and can pass various electrical performance technical tests.

2. No-clean solder paste NC: After the solder paste soldering is completed, the PCB surface is relatively smooth and has less residue. It can be tested by various electrical performance techniques and does not need to be cleaned again, which shortens the production process while ensuring the soldering quality, speeding up the production schedule.

3. Water-soluble solder paste WMA: After the solder paste welding work is completed, its residue can be cleaned with water, which not only reduces the production cost of customers, but also meets the requirements of environmental protection.

According to the melting point classification, solder paste is divided into three categories

1. High-temperature solder paste: High-temperature solder paste refers to the commonly used lead-free solder paste, the melting point is generally above 217°C, and the welding effect is good.

2. Medium temperature solder paste:Medium temperature solder paste, the commonly used lead-free medium temperature solder paste has a melting point of about 170°C. The characteristics of medium temperature solder paste are mainly the use of imported special rosin, which has good adhesion and can effectively prevent slumping.

3. low temperature solder paste:The melting point of the low-temperature solder paste is 138°C. The low-temperature solder paste is mainly made of bismuth. When the components of the patch cannot withstand the temperature of 200°C and above and the patch reflow process is required, use the low-temperature solder paste for welding, To protect the components and PCB that cannot withstand high temperature reflow soldering.

What Is The Use Of Soldering Paste?

Solder paste is mainly used for the soldering of electronic components such as PCB surface resistance, capacitors, and IC in the SMT industry. Solder paste has a certain viscosity at room temperature, which can initially stick electronic components in a given position. At the soldering temperature, with the volatilization of solvents and some additives, the soldered components and printed circuit pads are welded together to form Permanent connection.

The storage of solder paste has strict requirements:

1. Storage of unopened solder paste

If the solder paste is not opened, it should be placed in a refrigerator at 0~10°C for refrigeration, and cannot be frozen. If it is unopened solder paste, the rewarming has been completed, and it is not intended to be used in the next day, it should be returned to the refrigerator for storage. The same bottle of solder paste cannot be rewarmed more than twice, and it should be fed back to the process and quality department for processing.

2. Solder paste storage after opening

If the solder paste that has been opened after returning to temperature, if it is not used up in time, it should be stored with the inner cap on. For the lid, the solder paste processed by the above steps can be stored at the production site. In principle, after rewarming, the unsealed solder paste should be used within 24 hours. If it has been stored at the production site for more than 24 hours, it should be judged by the process quality technician before it can be used.

3. Store the solder paste without SMT printing and the printed solder paste separately

If the printed SMT solder paste is not used up in time, it should be recycled and stored in a clean empty solder paste bottle. The printed solder paste should not be mixed with the unprinted solder paste. Instead, it should be split-screen for storage. Make sure that the two will not interfere with each other.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt