86-571-26265158

The reflow soldering process is when the PCB with solder paste and well-mounted components enters the reflow soldering furnace. The PCB is driven by the reflow soldering rail transport chain to pass through the preheating zone, heat preservation zone, soldering zone, and cooling zone of reflow soldering in sequence. After the temperature changes of the four temperature zones of reflow soldering, the reflow soldering process of the circuit board is completed.

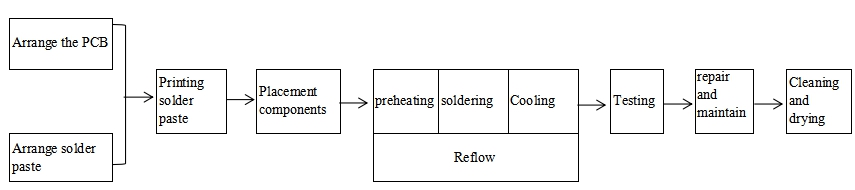

Figure 1 Reflow soldering process flow

Detailed explanation of reflow soldering process

1. When the PCB enters the preheating zone, the solvent and gas in the solder paste evaporate, and the flux in the solder paste wets the pads, component ends and pins at the same time. Then the solder paste softens, collapses, and covers Pads, isolate pads and component pins from oxygen.

Preheating is to activate the solder paste, and to avoid the rapid high temperature heating during immersion in the tin, which is a heating action to cause defective parts. The goal of this area is to heat the PCB at room temperature as soon as possible, but the heating rate should be controlled within an appropriate range. If it is too fast, thermal shock will occur, and both the circuit board and components may be damaged. If it is too slow, the solvent will not evaporate sufficiently and affect Welding quality. Due to the faster heating speed, the temperature difference in the reflow furnace at the back of the temperature zone is larger. In order to prevent thermal shock from damaging the components, the maximum heating rate is generally specified as 4°C/S, and the rising rate is usually set at 1~3°C/S.

2. When the PCB enters the heat preservation area, make the PCB and components fully preheated to prevent the PCB from suddenly entering the welding high temperature area and damaging the PCB and components.

The main purpose of the heat preservation stage is to stabilize the temperature of the components in the reflow furnace and minimize the temperature difference. Give enough time in this area to make the temperature of the larger component catch up with the smaller component, and to ensure that the flux in the solder paste is fully volatilized. At the end of the heat preservation section, the oxides on the pads, solder balls and component pins are removed under the action of the flux, and the temperature of the entire circuit board is also balanced. It should be noted that all components on the SMA should have the same temperature at the end of this section, otherwise, entering the reflow section will cause various bad soldering phenomena due to the uneven temperature of each part.

3. When the PCB enters the soldering area, the temperature rises rapidly to make the solder paste reach a molten state, and the liquid solder wets, diffuses or reflows the PCB pads, component ends and pins to form solder joints.

When the PCB enters the reflow zone, the temperature rises rapidly so that the solder paste reaches a molten state. The melting point of the lead solder paste 63sn37pb is 183°C, and the melting point of the lead solder paste 96.5Sn3Ag0.5Cu is 217°C. In this area, the heater temperature is set high, so that the temperature of the component rises rapidly to the peak temperature. The peak temperature of the reflow soldering curve is usually determined by the melting point temperature of the solder and the heat resistance temperature of the assembled substrate and components. In the reflow section, the peak soldering temperature varies depending on the solder paste used. Generally, the high temperature of lead-free is 230-250°C, and lead is 210-230°C. If the peak temperature is too low, it is easy to produce cold joints and insufficient wetting. If the peak temperature is too high, coking and delamination of the epoxy resin substrate and plastic parts are likely to occur.It will excessive eutectic metal compounds will be formed, which will lead to brittle solder joints and affect solder strength .

In the reflow soldering area, pay special attention to the reflow time not to be too long, to prevent damage to the reflow furnace, it may also cause poor functions of the electronic components or cause the circuit board to be burnt.

3. The PCB enters the cooling zone and the solder joints are solidified.The reflow soldering is completed.

At this stage, the temperature is cooled to below the solid phase temperature to solidify the solder joints. The cooling rate will affect the strength of the solder joint. If the cooling rate is too slow, it will cause excessive eutectic metal compounds to be produced.Large grain structures are prone to occur at the welded joints, which will lower the strength of the welded joints. The cooling rate in the cooling zone is generally about 4°C/S, and the cooling rate is 75°C.