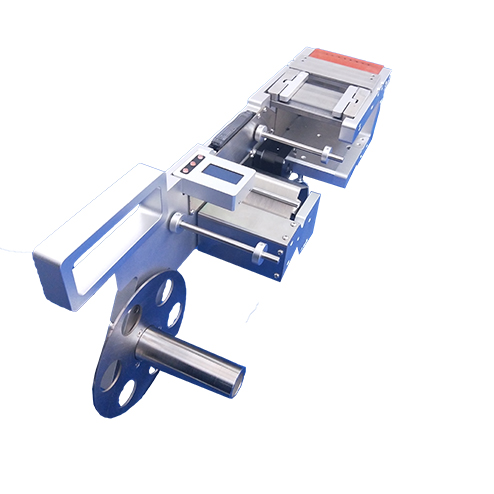

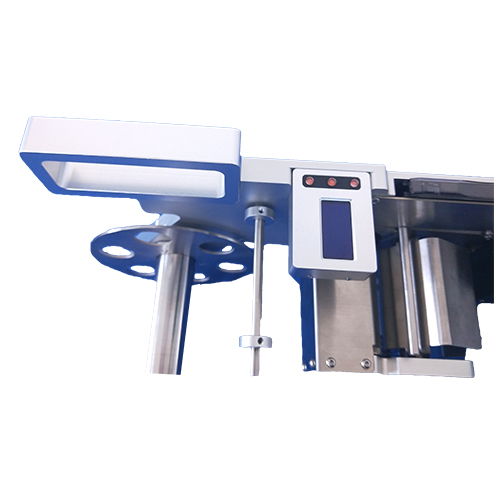

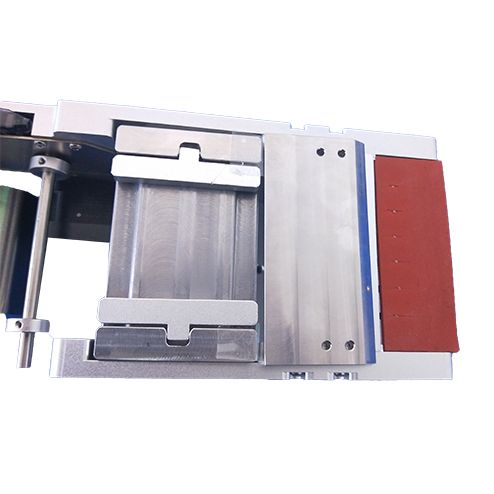

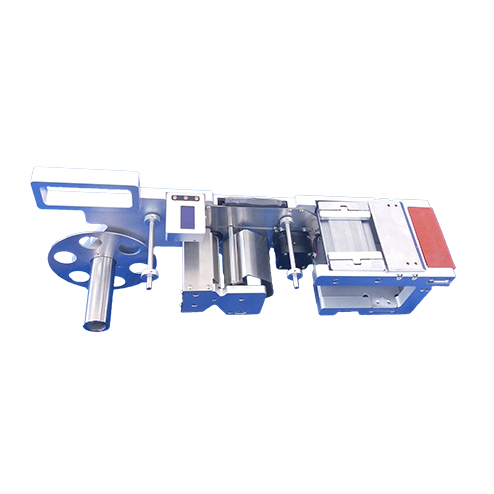

About of Label Feeder

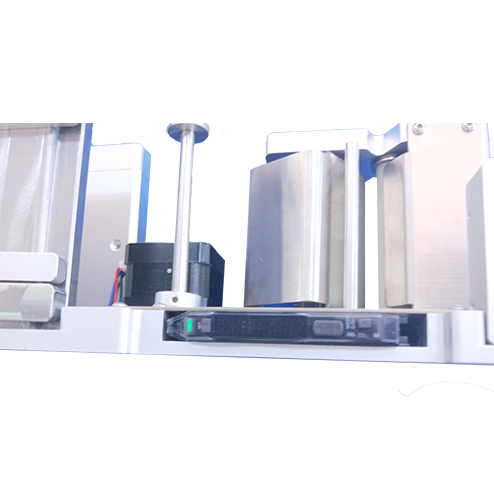

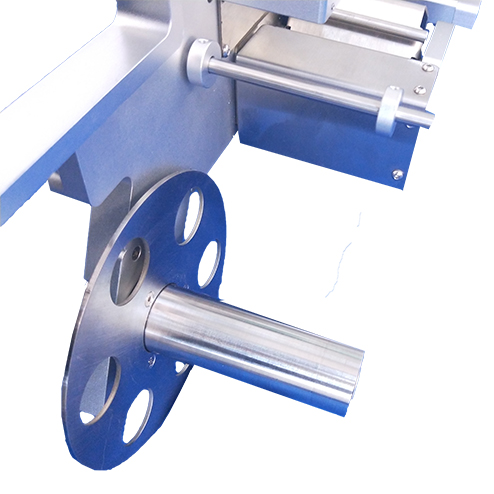

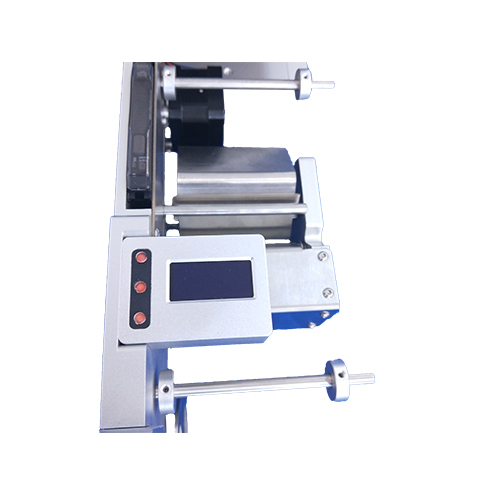

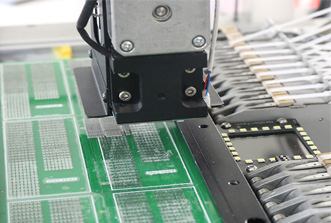

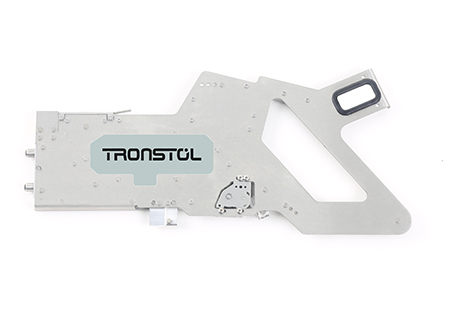

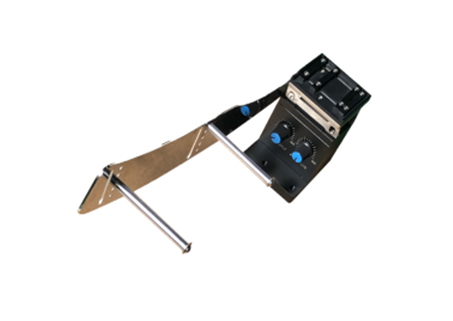

Tronstol SMT Label Feeder For Tronstol A1 Pick and Place Machine

The easiest and cheapest way of marking a product automatically is the application of a label with a label feeder. The feeder can be integrated in the automatic pick and place machine and the label will be simply placed like a standard component – precisely and in line speed.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt