Tronstol A1 Pick and Place Machine with Semi-Automatic Solder Printer YS 600 and Tronstol Reflow Oven L8 - Economical Assembly Production SMT Line.

86-571-26265158

Tronstol A1 Pick and Place Machine with Semi-Automatic Solder Printer YS 600 and Tronstol Reflow Oven L8 - Economical Assembly Production SMT Line.

| Model | YS600 |

| PCB size | Max:600*240mm |

| Printing area | 700*320mm |

| PCB fixed system | Pin positioning |

| Frame size | L(370-750)*W(470-850) |

| Adjusting for table | front/rear±10mm,left/right±10mm |

| Printing Accuracy | ±0.2mm |

| Repeating Accuracy | ±0.2mm |

| PCB thickness | 0.2-2.0mm |

| Air source | 4-6kg/c㎡ |

| Power supply | AC220V 50HZ |

| Dimension | L900*W700*H1700mm |

| Packing size | 1350*900*1850mm |

| Net weight | 265kg |

| Gross weight | 310kg |

1. This model is controlled by PC, touch screen display and menu operation interface

2. It uses a floating scraper, which needs to be powered by an air pump. The scraper can float up and down freely and can be automatically adjusted to be level with the steel grid.

3. The pressure of scraper can be adjusted according to the length of scraper.

4. The process of removing the steel strip from PCB can be adjusted between 0 and 5 seconds

5. Press the button with both hands to ensure safety and reliability.

6. The stop time of the scraper at the top left, bottom left, bottom right and upper right as well as the total stop time of the steel grid at the top or bottom can be set independently in the touch screen menu.

7. PCB can be positioned and fixed through bottom hole, bottom edge, bottom hole and bottom edge as well as template positioning. The firmness of fixation affects the accuracy of solder paste printing.

8. The time can be displayed on the touch screen and the printing time can be recorded.

9. The speed of left and right scraper can be adjusted, and it can be stopped in case of emergency.

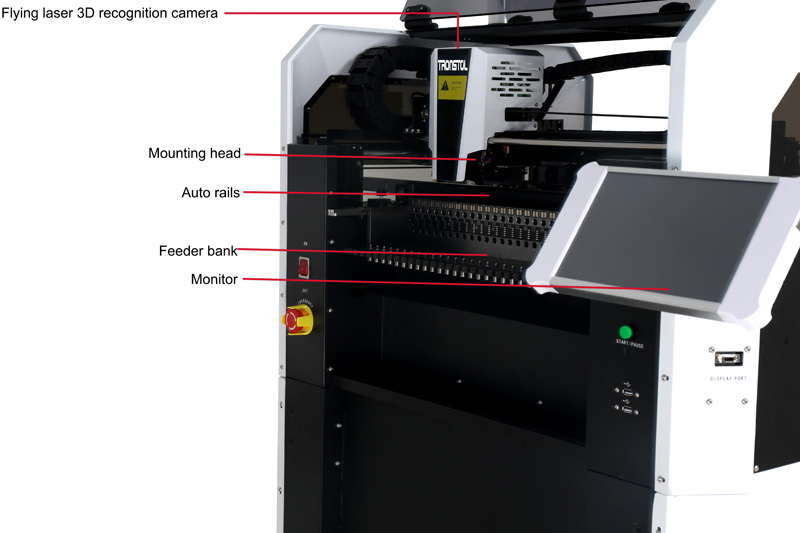

You can click Pick And Place Machine Tronstol A1 to learn its specification & features.

| Model | L8 |

| Components Max Height (CM) | 5.5 |

| Conveyor Width(CM) | 30 |

| Max Speed of Conveyor (CM) | 120 |

| Peak Power(KW) | 12 |

| Working Power(KW) | 5 |

| Input Voltage(V) | 380/220 |

| 8 heating zones | First: Fast preheat zone,Second/Third: Drying zones,Fourth: Soldering zone,Fifth/Sixth/Seventh/Eighth: Bottom side heat zones,(Each zones adapts independent heating/cooling control ways, cooling zone belongs to strong wind refrigerating system.) |

| External Dimensions | Machine:210*70*128CM |

| Net Weight | 300KGS |

| Gross weight | 450kg |

1. L8 uses hot air quota method to solder PCB. It supports various conventional components, LEDs and various ICs.

2. It uses a crawler structure. When matched with eight heating zones, it can make the internal temperature more accurate and uniform. It only takes 15-20min to reach the working temperature.

3. It adopts AC motor to drive the conveyor belt and adopts chain drive mode. The speed regulation is controlled by an automatic electronic analog switch, which is easy to operate. Its sensitivity does not exceed 1 degree, and its control accuracy is ±10mm/min.